Things to know about shale gas

4

Hydraulic fracturing

Hydraulic fracturing, is a tried and tested, controlled,

and technologically advanced process that employs

well-known laws of physics. Its aim is to create such

conditions inside the well as to make the extraction of

natural gas (from shale rock, among others) possible.

Also known as ‘hydrofracturing‘, it has been known

and used for many years. It was first used in the

1940s and the technology has been continuously

improved and successfully used worldwide ever

since. So far over 2,000,000 instances of hydro-

fracturing have been carried out.

Hydrofracturing is the final stage in the process of

reservoir exploration, and it results in gas flowing

into the well and on to the surface. Hydrofracturing

is always preceded by a preparatory stage, which

may take months or years, and includes analysing

seismic and geological data, performing test dril-

ling, studying the petrophysical and geomechani-

cal features of rock cores, etc.

A detailed analysis of the reservoir properties

allows a flawless preparation and optimisation of

the hydrofracturing process. The work, in spite

of the fact that it is carried out several kilometres

under the surface of the ground, requires cloc-

kwork precision.

The process of hydrofracturing entails pumping

fluid (known as fracturing or stimulation fluid) into

the well. Over 99% of the stimulation fluid consists

of water mixed with sand. Depending on the con-

ditions in the reservoir and the well, it also contains

a small addition of other substances that make hy-

drofracturing more effective. A single well requires

an average of between 8,000 m

3

and 14,000 m

3

of water and 450 to 680 tonnes of sand, but the

exact figures depend on the length of the 5-inch-

-diameter horizontal well, which is where hydro-

fracturing takes place. The chemical additives in

the stimulation fluid are there to prevent the corro-

sion of pipes (bactericidal substances), reduce the

settling of the sand (gelling agents), and to prevent

fluid viscosity from fluctuating. The actual compo-

sition of the fluid is determined on a case-by-case

basis and it ultimately depends on the properties of

the gas reservoir in question.

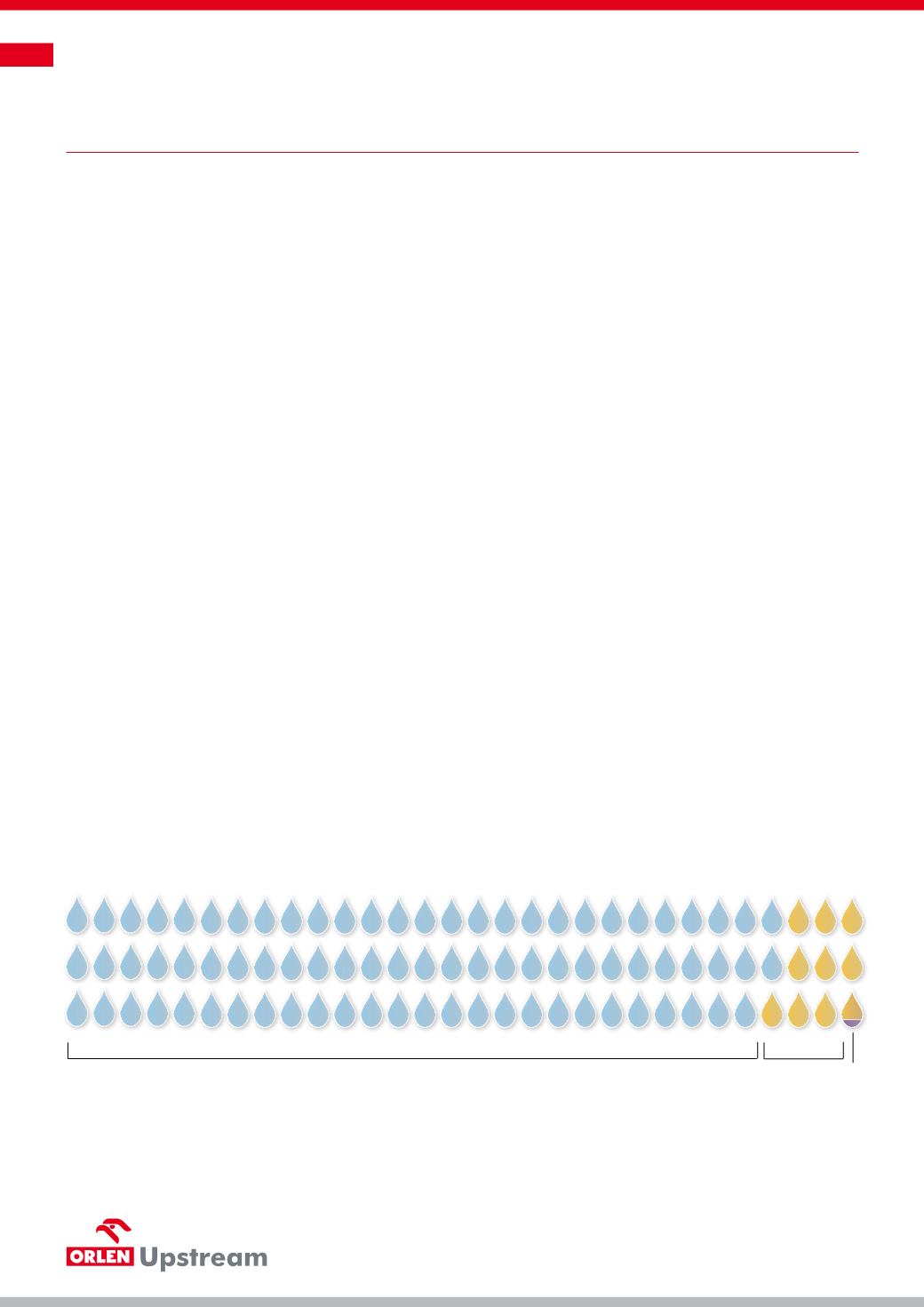

Composition of the stimulation fluid

Chemical

additives

~ 0,1%

Water

Sand

~ 95%

~ 5%